Repulsive-Point-Thermo-Elasticity

for Solids at Extreme Pressures and Temperatures based on Shear

An Excellent Way to predict the Elastic Properties of Solids

An Important Method to Measure Pressure and Temperature in Solids

The Graphs Below Highlight a Selection of the Materials Studied

updated on October 30, 2023

Repulsive point

thermo-elasticity is used in reference [8] to describe the temperature and

pressure dependence of the shear modulus in solids. The figures posted are based on a completely

new constitutive law: the shear modulus only depends on the volume as a

state-variable of the solid. The volume

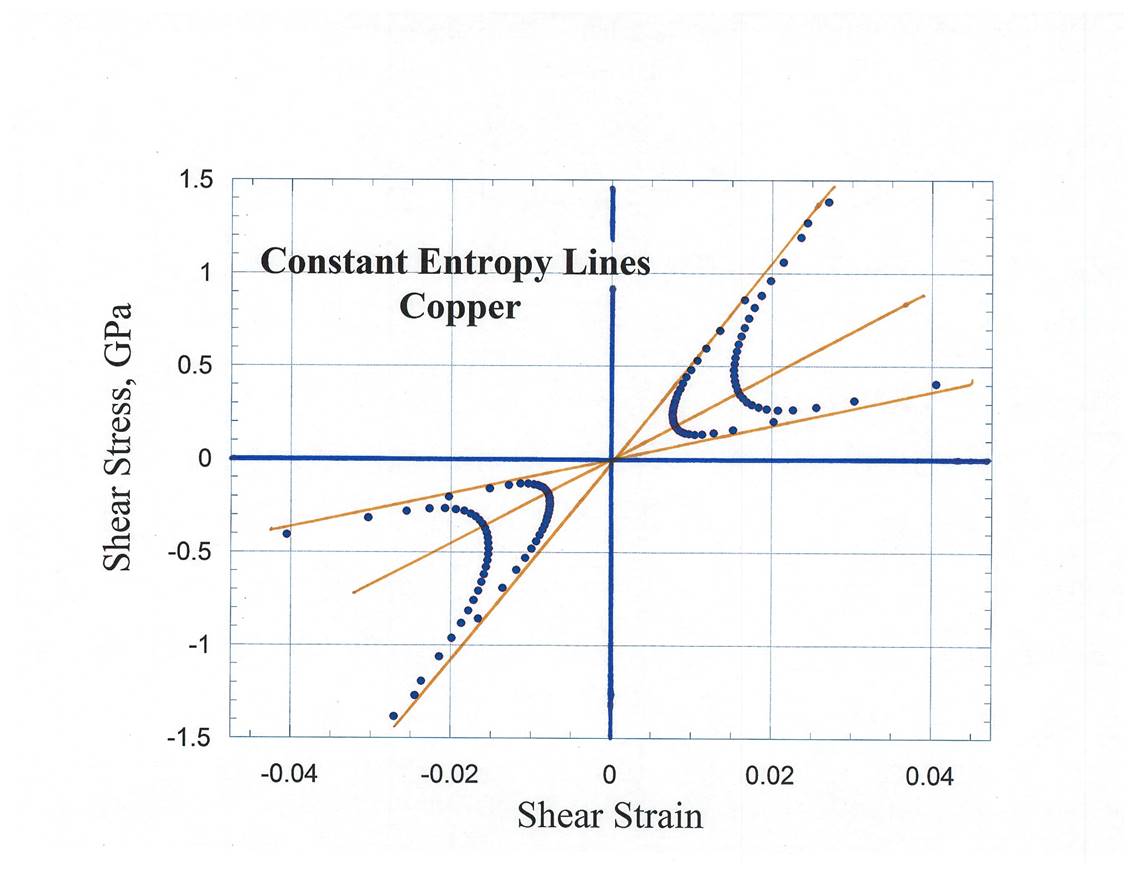

in-turn is dependent on the temperature and the pressure. Swenson’s law from 1968 states that the ‘shear

modulus of a solid does not depend on temperature or pressure when the specific

volume is held constant’. This implies

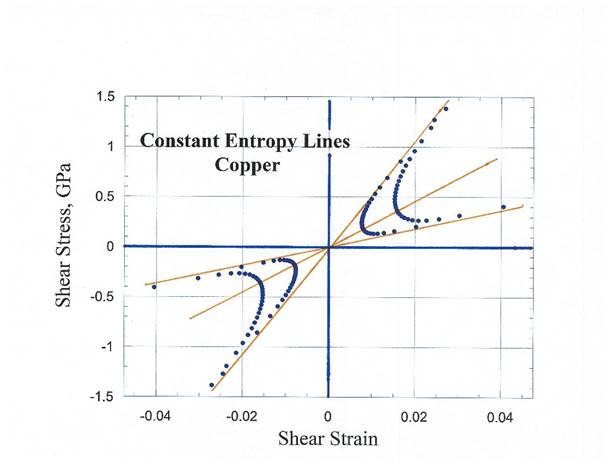

that the entropy lines in shear stress vs shear strain at selected temperatures

are going to cross which is not possible.

The entropy lines in shear are pushed away from the point where the

isothermal lines cross i.e., zero shear stress and zero shear strain point.

There is now a growing

body of evidence of the applicability of this ‘universal modulus law’ in a wide

selection of materials including metals, ceramics, minerals and (soon to be

investigated polymers and glasses). The

bulk moduli in some single-phase, elemental metals, Na, Cu, Au and Ag were used to establish

that the law is truly universal. The

rule to follow is that the material must support a shear stress, i.e., behave

as a solid.

Go to the materials

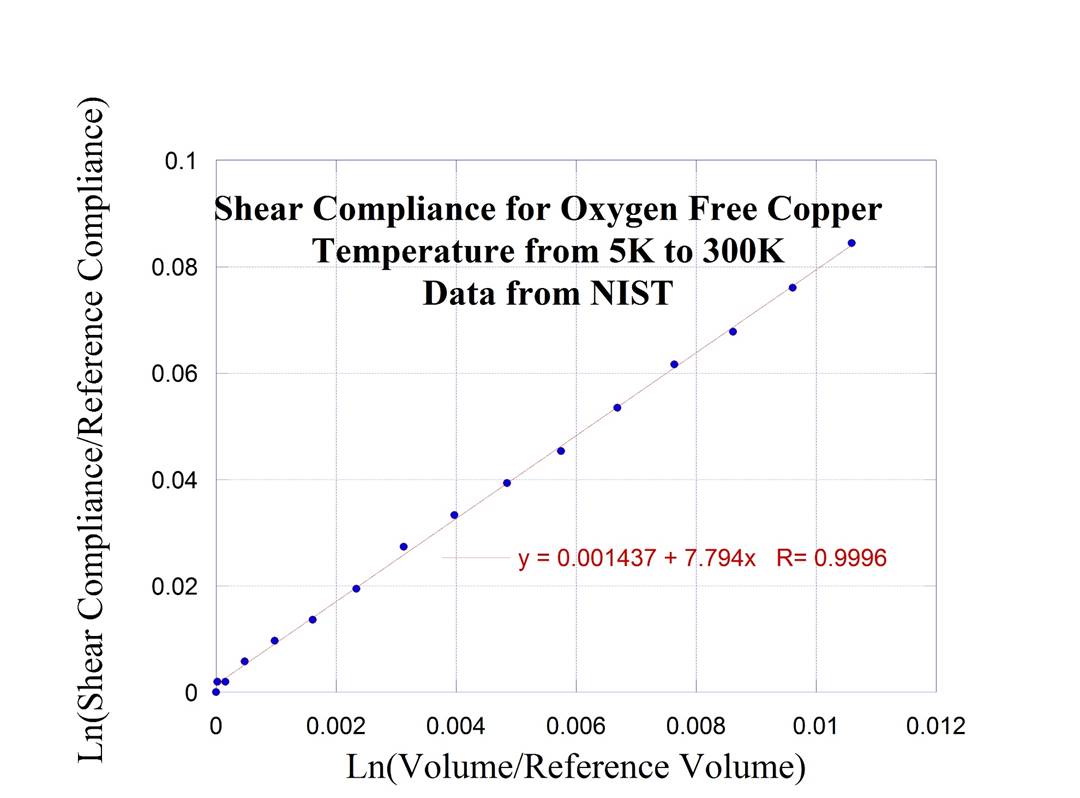

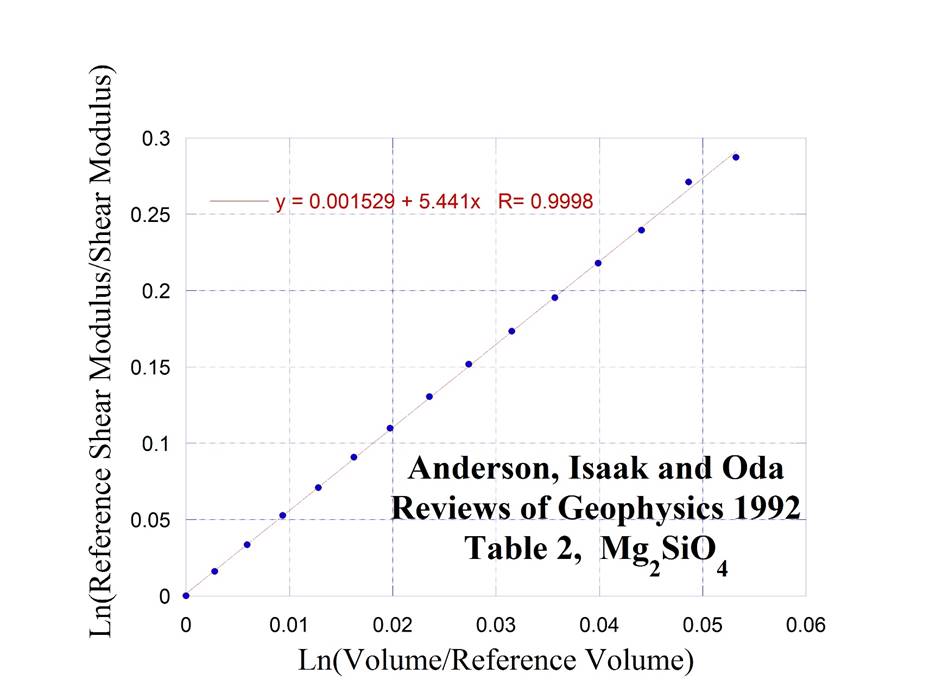

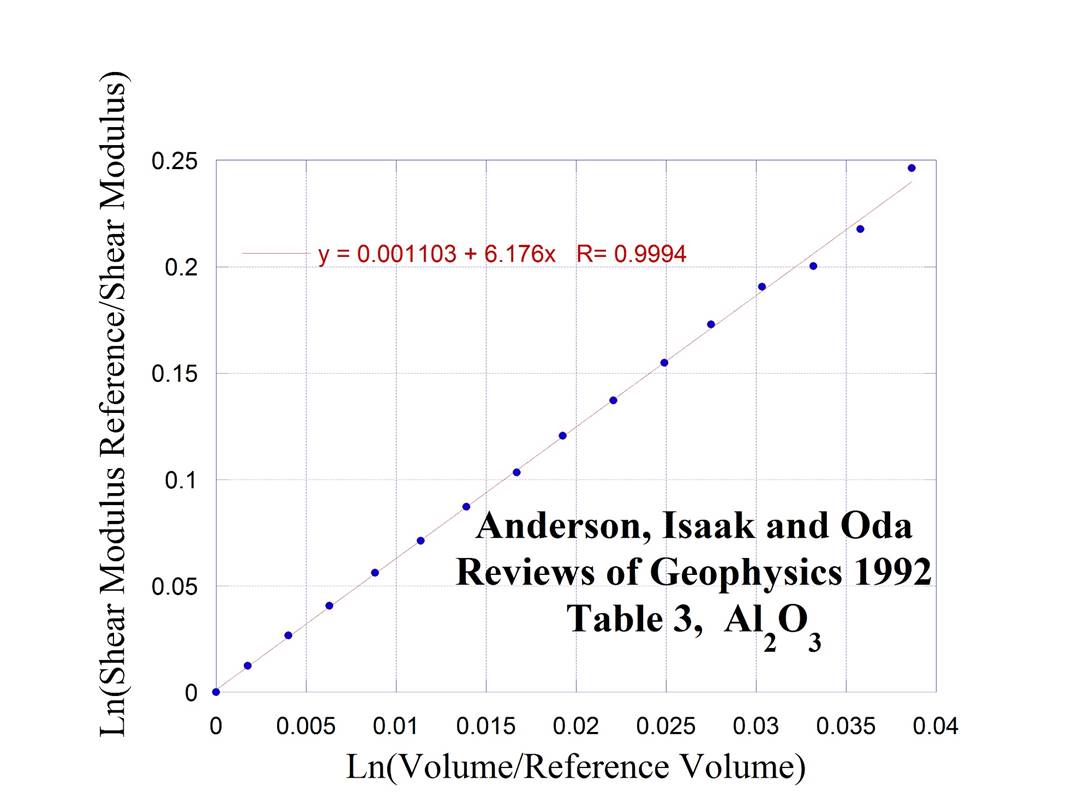

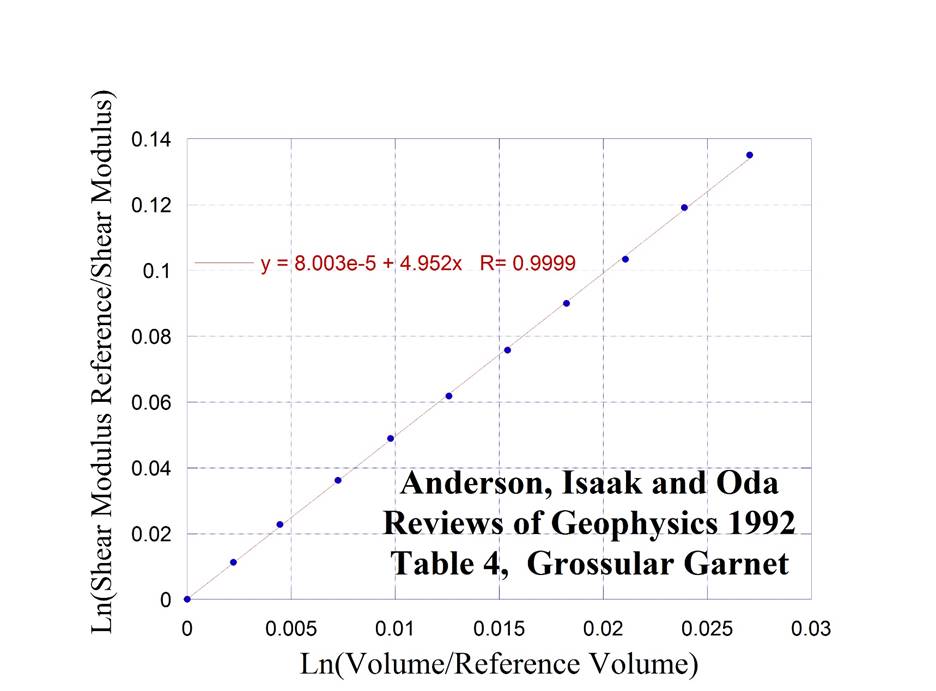

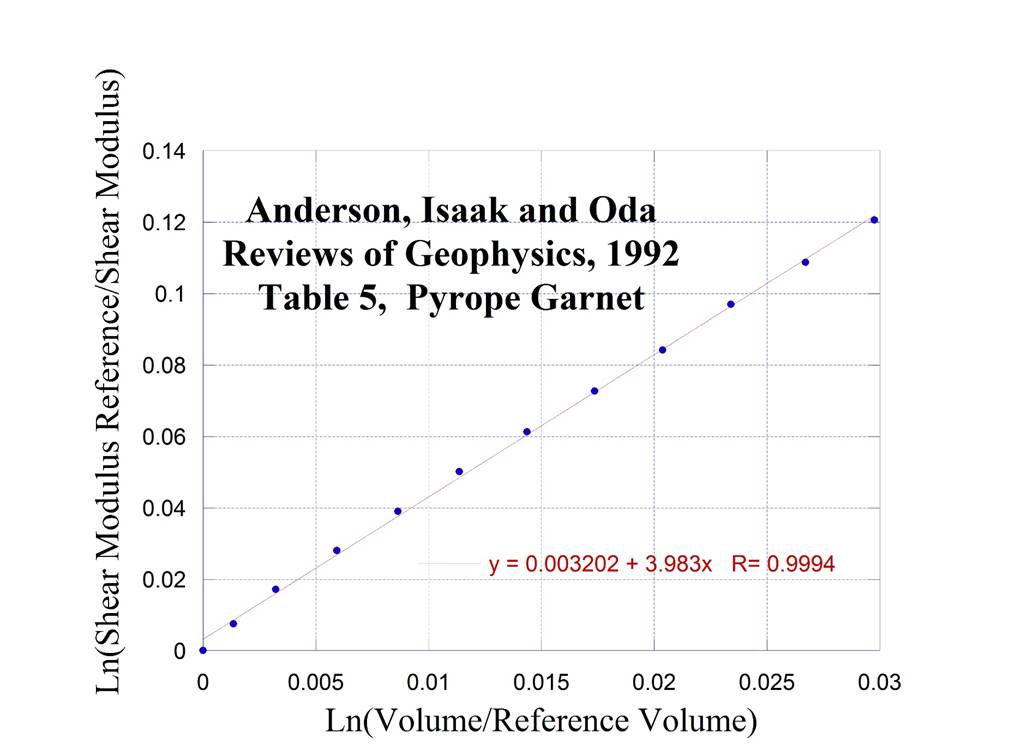

listed below for some of the materials studied {I now have an additional 20 materials in September 2022} I have constructed plots of the log natural

(Compliance/Reference Compliance) versus the log natural of the (Volume/Reference

Volume).

1.

Copper

2.

Ringwoodite

3.

α Alumina

4.

Grossular Garnet

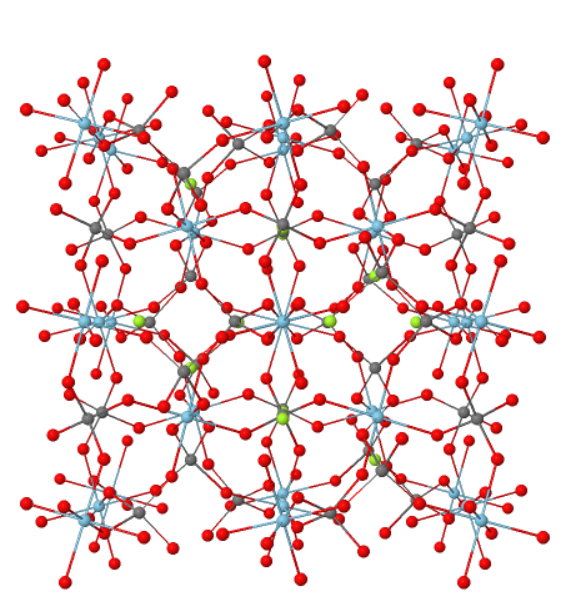

Garnet – Ca3Al2Si3O12 – Grossular

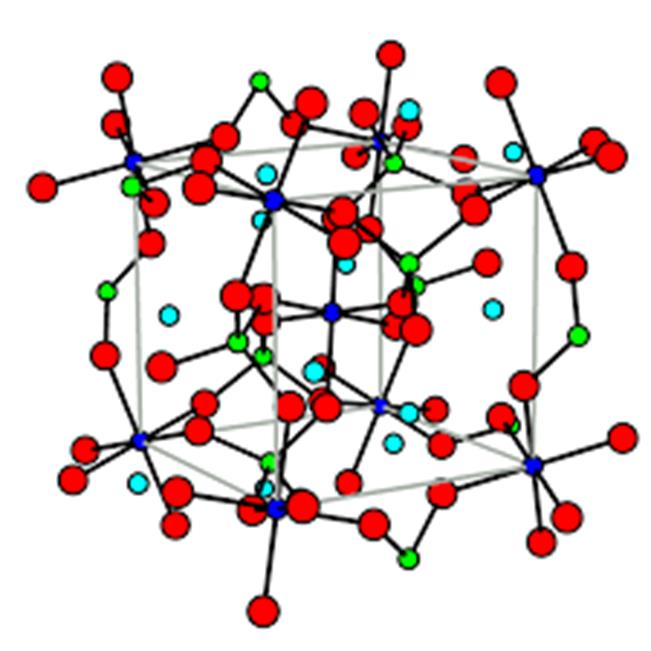

5. Pyrope Garnet

6.

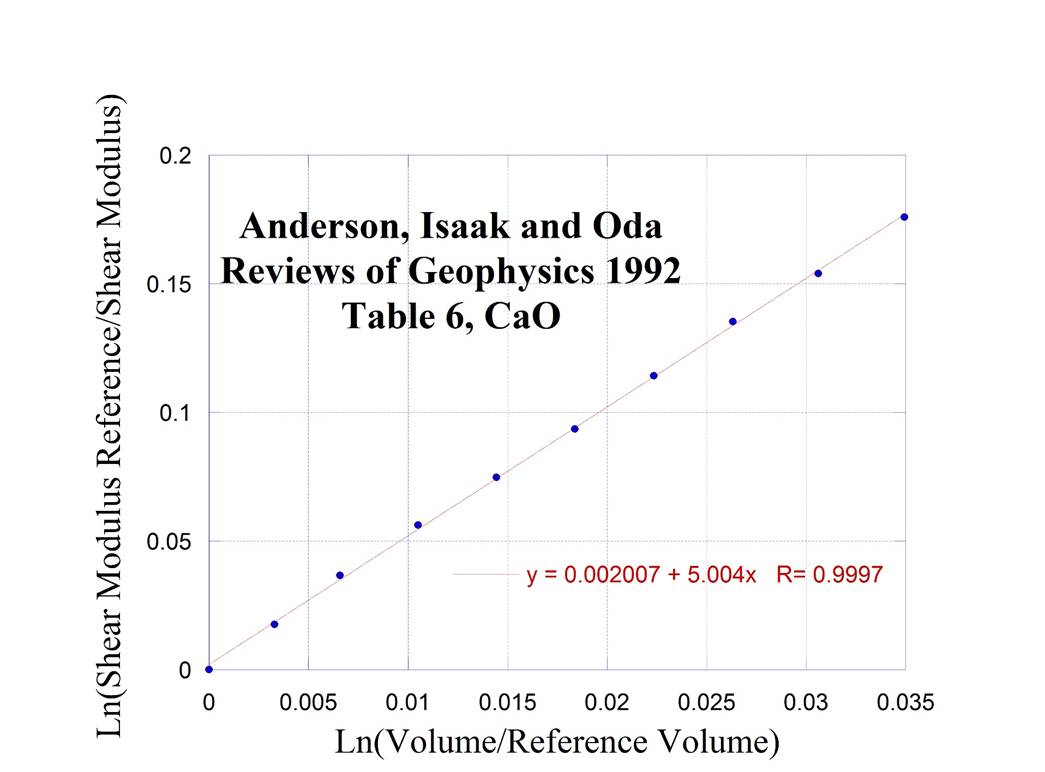

Quicklime

or CaO

7.

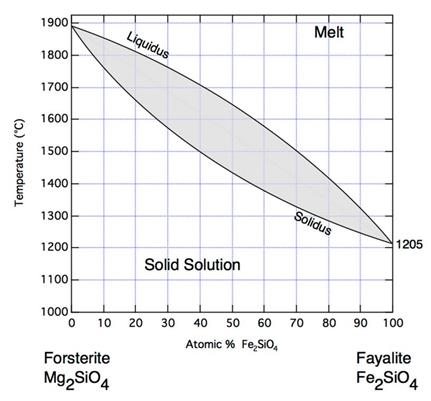

Forsterite

and Fayalite are a solid solution on the temperature composition axis

On

the pressure composition axis the (Mg, Fe)2SiO4

system forms Olivine I and Olivine II compositions

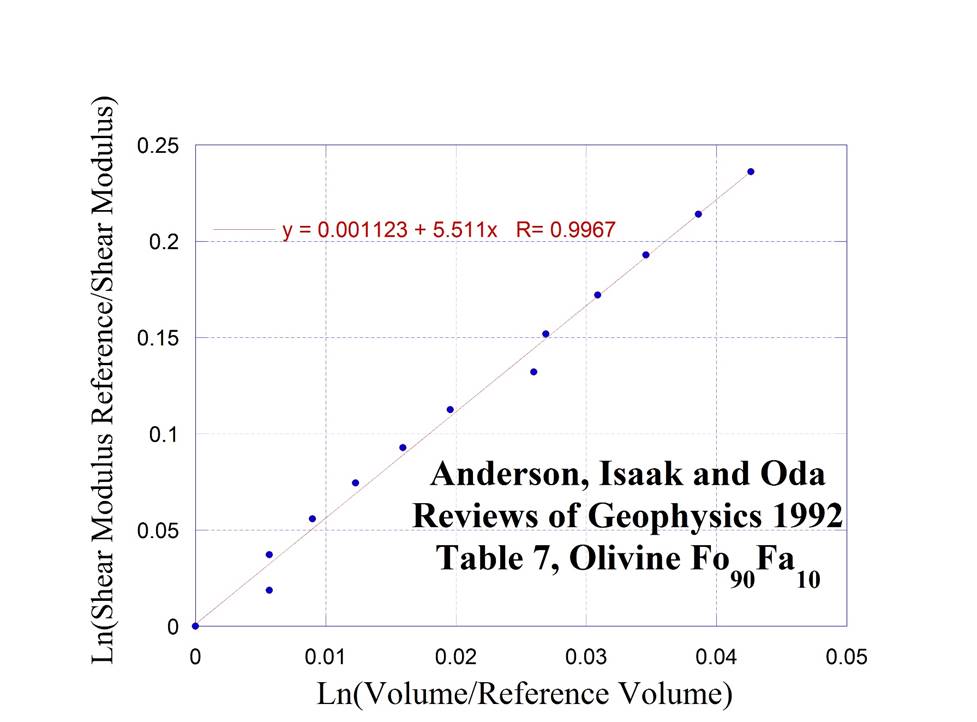

Olivine I

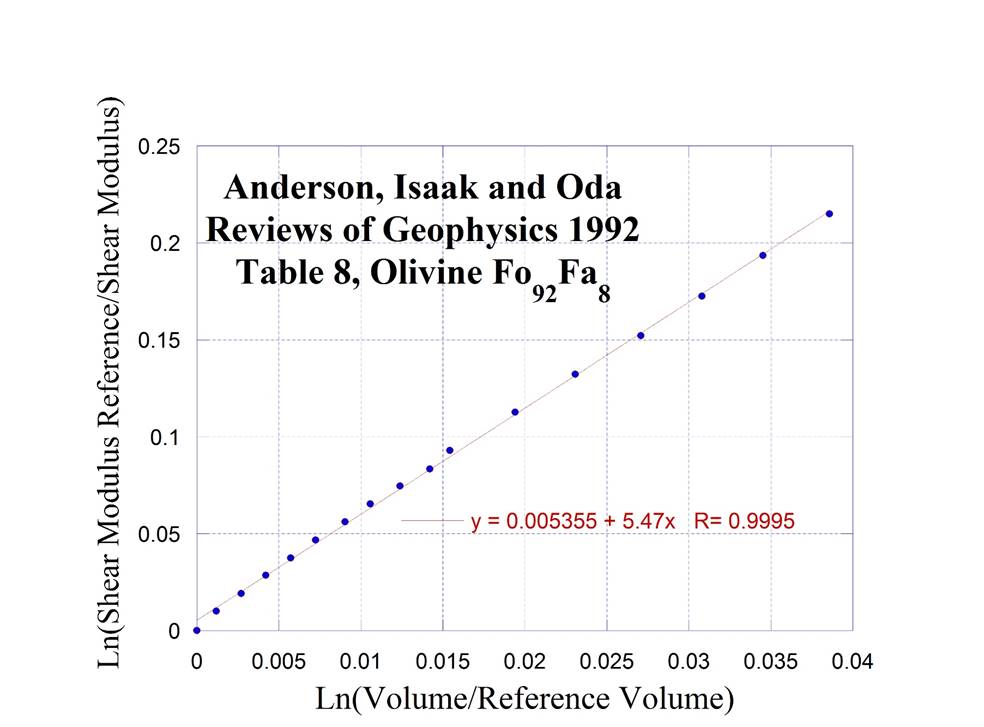

Olivine II (with

a slightly different composition in Fe see structure in Olivine I)

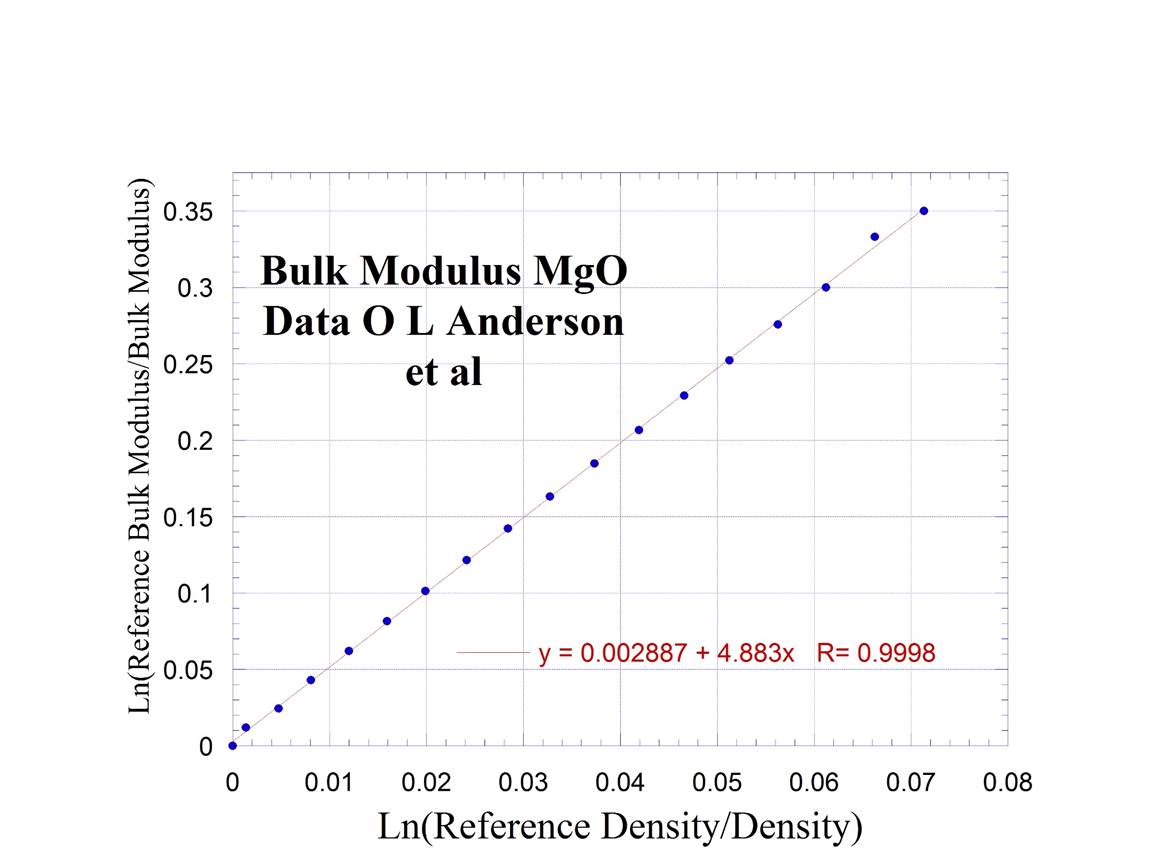

8.

Periclase

or Polycrystalline MgO

9.

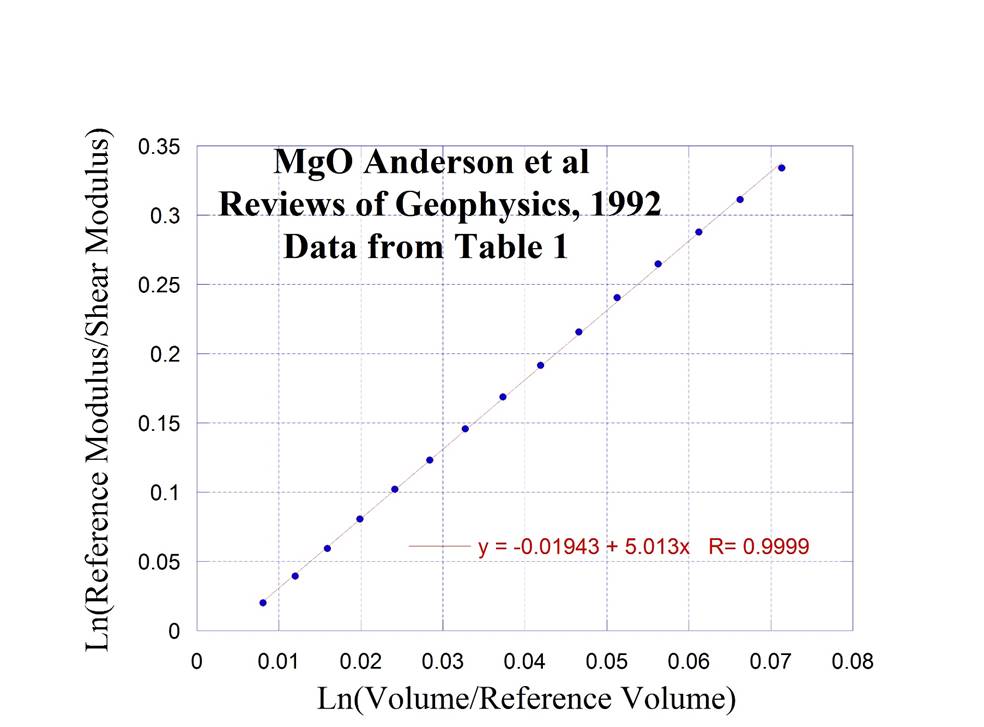

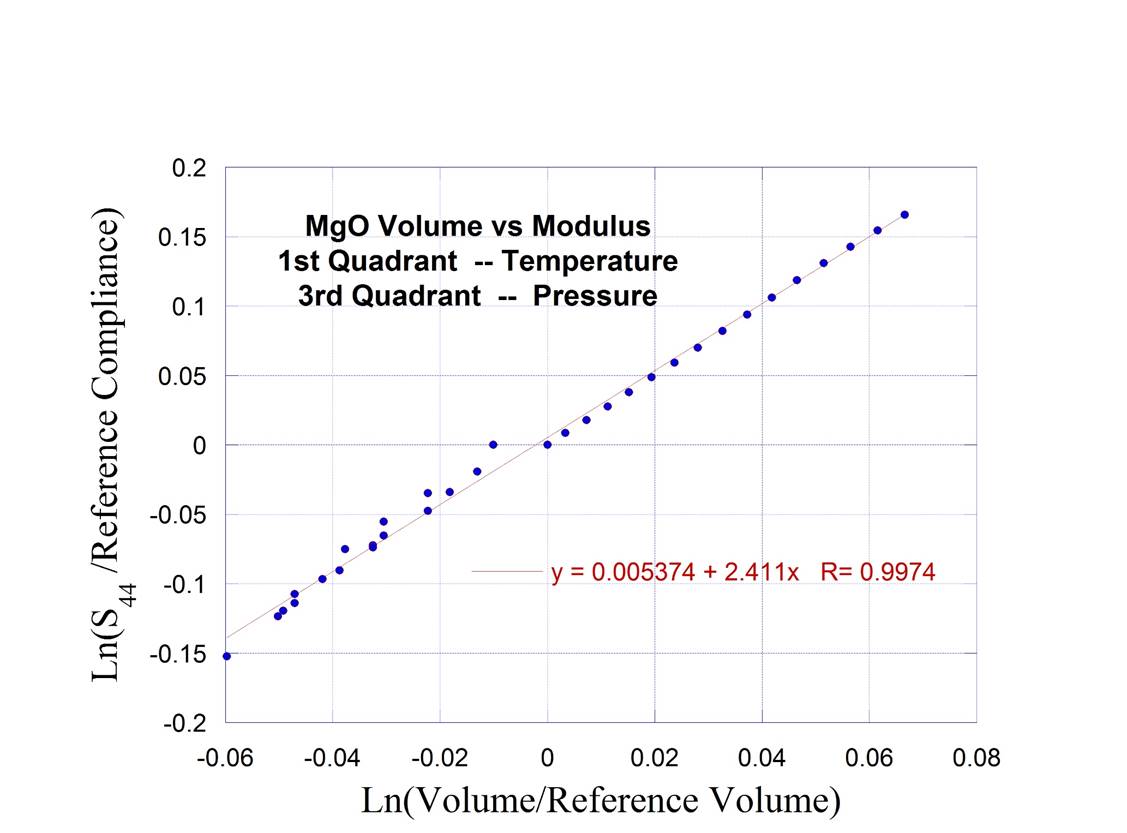

Single

Crystal MgO (with

temperature and pressure parametrically on same graph)

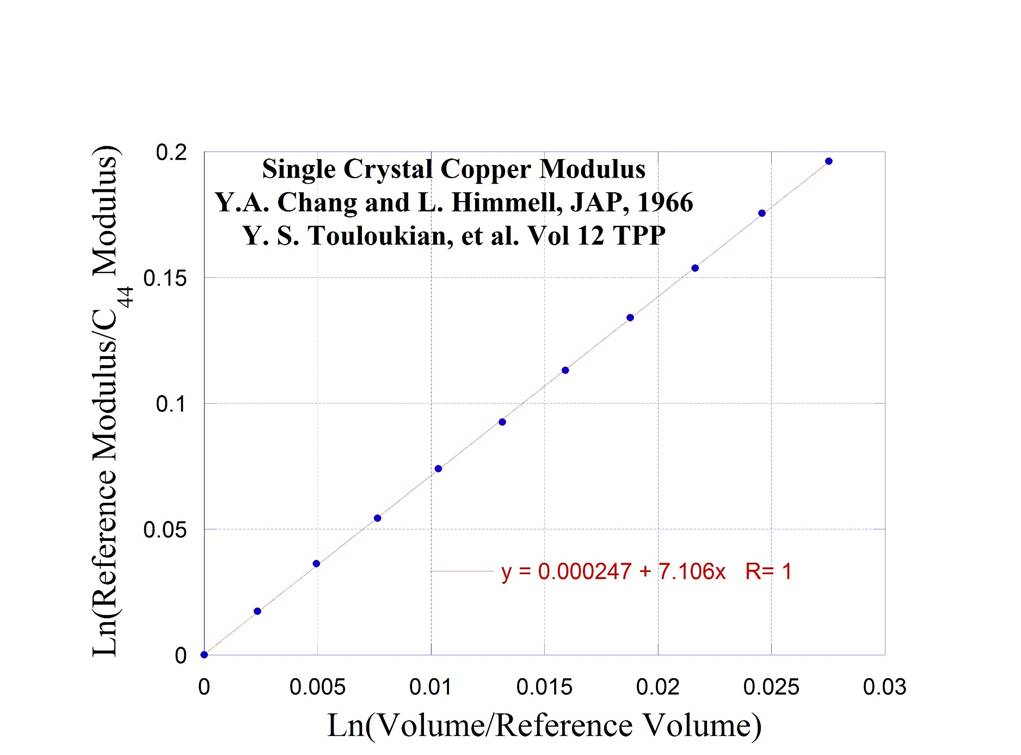

10. Single

Crystal Copper at High Temperature (see #1 for

polycrystalline copper at low temperature)

11. Construction

of Constant Shear Entropy Lines for Copper

12. Bulk

Modulus from Polycrystalline MgO