Anthamatten lab develops new self-stretching material

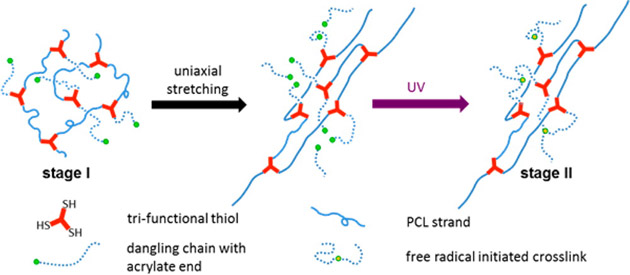

(This illustration shows the preparation of dual-cure network stress-free actuators as part of a paper, Shape Actuation via Internal Stress-Induced Crystallization of Dual-Cure Networks, published by the Anthamatten group inACS Macro Letters. See additional illustrations at bottom.)

Although most materials slightly expand when heated, there is a new class of rubber-like material that not only self-stretches upon cooling; it reverts back to its original shape when heated, all without physical manipulation.

The findings were recently published in the journal ACS Macro Letters.

The material is like a shape-memory polymer because it can be switched between two different shapes. “However, unlike other shape-memory polymers, the material does not need to be programmed each cycle—it repeatedly switches shapes, with no external forces, simply upon cooling and heating,” said Mitchell Anthamatten, an associate professor of chemical engineering.

The material is like a shape-memory polymer because it can be switched between two different shapes. “However, unlike other shape-memory polymers, the material does not need to be programmed each cycle—it repeatedly switches shapes, with no external forces, simply upon cooling and heating,” said Mitchell Anthamatten, an associate professor of chemical engineering.

Anthamatten and his team built on the success of a recently developed polymer that can also stretch when cooled. The other polymers need to have small loads—or weights—attached in order to direct the shape to be taken. That is not the case with the Rochester polymer, because Anthamatten’s team “tricked it into thinking” a load was attached.

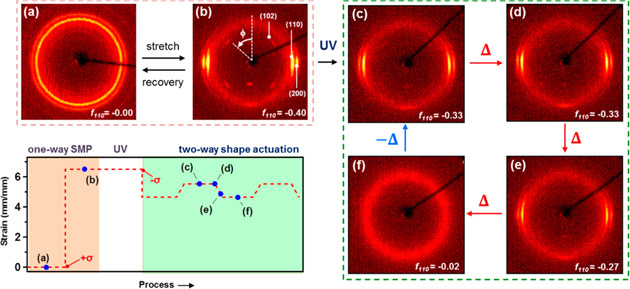

To carry out their strategy, the researchers introduced permanent stress inside the material. They began with polymer strands that were loosely connected by bonds called crosslinks that create a network of molecules. The material was stretched with a load attached to give it the desired shape. At that point, they added more crosslinks and cooled the polymer, causing crystallization to occur along a preferred direction.

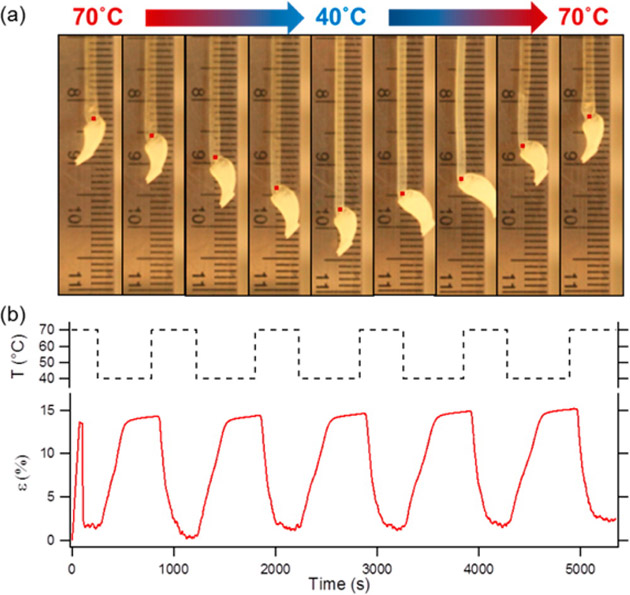

Anthamatten’s team showed that internal crystallization forces are strong enough to stretch the material along one direction. Once cooled below about 50 °C, polymer chain segments pack into highly ordered micro-layers called lamellae. This reorganization occurs within a network of polymer chains, causing the material’s length to increase by over 15 percent.

“The stress we built into the network takes the place of the load and enables the material to ‘remember’ the shape it will assume when it’s later cooled without a load,” said Anthamatten.

Conventional shape-memory polymers need to be reprogrammed after each cycle, but that’s not the case with the material developed by Anthamatten and his team. After multiple cycles of cooling and heating, they found that the material assumed its programmed shape and returned to its initial state with no noticeable deviation.

Anthamatten envisions the material being applied to a number of areas in which reversible shape-changes are needed during operations, including biotechnology, artificial muscles, and robotics.

“The next step is to optimize the shape of the polymer material and the energy released during the process,” said Anthamatten. “That will be done by adjusting the type and density of crosslinks that tie the individual chains together.”

The research team included two of Anthamatten’s students—Yuan Meng and Jisu Jiang. The work was supported internally by the University of Rochester’s Pump Primer Seed Grant Program, which exists to support proof-of-concept studies.

(Reported by Peter Iglinski.)

Actuation behavior of samples cured at an extension ratio of 650%. (a) A specimen with a gauge length of 8.3 cm (red dot), measured at 70 °C, under no external load, elongated to 9.7 cm, upon cooling to 40 °C, and reversibly returned to its initial length, upon heating to 70 °C. The white part on the bottom end of the sample is the grip used to hold the sample during MTS tests. The grip does not show actuation behavior. (b) Evolution of tensile extension over five cooling–heating cycles, showing 14% actuation.

Measured sample dimensions and WAXS data illustrating how UV fixation transforms the specimen from a one-way shape-memory polymer to a two-way shape actuator. Bottom left: strain for a PCL Stage I network that is stretched to 650%, photocured, and thermally cycled without applied stress. The annotations (+σ) and (−σ) indicate when the load was applied and removed. The blue data points indicate measured strain values, and the dashed line is meant to guide the eye. The rest: evolution of WAXS patterns at different stages as the material is converted from one-way shape-memory polymer (red box) to a two-way shape actuator (green box): (a) Stage I network in the unstretched state. (b) Stage I network stretched to 650%. (c) The network after Stage II curing—UV irradiation at 650% strain—followed by unloading and cooling to room temperature. (d, e, and f) The same network after heating to 40 °C, 55 °C, and 70 °C, respectively. The Herman orientation factor of the (110) planes is included in each WAXS image.