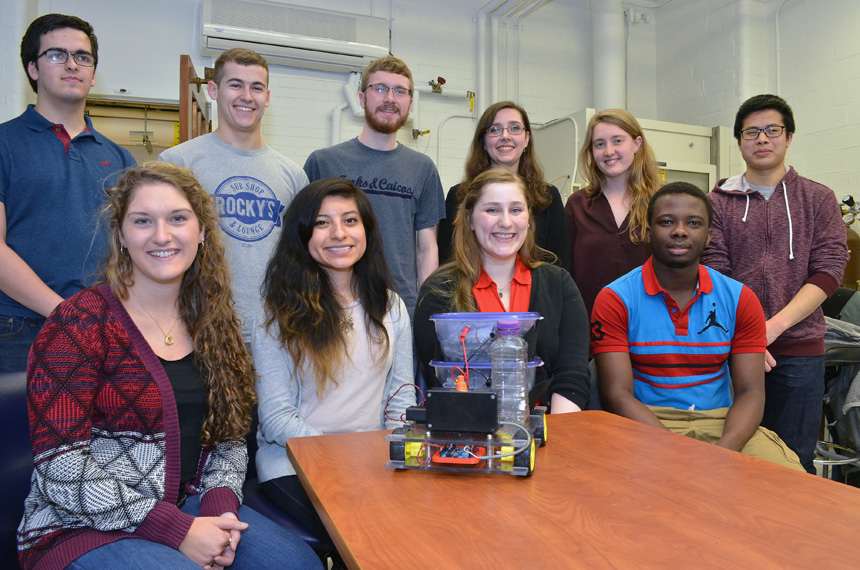

Chem-E-Car team shows its spirit at regional competition

Members of the Chem-E-Car team with the vehicle they designed, built and entered in a regional contest at Worchester Polytechnic Institute. They include (front row left to right) Amelia Petrosino, Reyna Juarez Martinez, Elizabeth Mauser, Aime Laurent Twizerimana, and (back row, left to right) William Potter, Ellison Etnier, Alexander Lamothe, Melissa Becker, Emily Volk, and Charles Chiang. (Photos by Bob Marcotte/University of Rochester)

Members of the fledgling Chem-E-Car team at the University of Rochester were excited to go head to head against powerhouse teams from Cornell and McGill at their first-ever regional competition recently.

“Honestly, just getting to the competition and passing the safety component – we were ecstatic,” says Elizabeth Mauser ’17, who, with fellow senior Reyna Juarez Martinez, began organizing the team in earnest last school year.

Safety is paramount – and stringently enforced -- at the competitions sponsored by the American Institute of Chemical Engineers (AIChE). The events feature vehicles students build from scratch, powered by chemical reactions. Teams are given two attempts to deliver a load of water as close as possible to a distance determined an hour before the competition begins.

The chemical engineering students, all members of the University’s AIChE student chapter, finished tied for 11th among 13 qualifying teams in the March 26 event at Worchester Polytechnic Institute in Massachusetts. They didn’t have big corporate sponsors and funding behind them, like some of the other teams. But they impressed the judges nonetheless. “They said we were the most enthusiastic team,” says Melissa Becker ’17.

The Rochester vehicle was powered by a reaction of aluminum and oxygen. “Basically we used aluminum foil with activated carbon, which has pockets of air,” explains team member Alexander Lamothe ’17. “We just rolled it up into small burrito-like cells (16 in all, in two separate compartments) with salt solution as the conductive medium.”

Coming up with that part of the design “took the longest amount of time to figure out,” Lamothe says. “Even towards the end we weren’t really sure we would get the right amount of power, and had to switch out the design of the batteries.”

And that was ultimately the team’s undoing when the competition got underway.

The Rochester students were the first to the start line. Alas, they couldn’t get their vehicle to move -- on either try.

“We just needed a little more power . . . Just a few extra cells and it would have started moving,” Lamothe says.

The students are taking the setback in stride. “As I said, we tied for 11th,” Mauser says, laughing good-naturedly. “So two other cars didn’t move either.”

They recognize that this is part of a learning curve, which began just over a year ago when Mauser and Juarez Martinez were the team’s only members, struggling to master car design and safety procedures.

“This project was all about learning as we went,” Juarez Martinez says. “Trying to recruit and retain members, that was the hardest part. This year we had a core group that kept coming back, and that encouraged us to keep going with it.”

Team members say they’re grateful for the advice and support they received from faculty and staff within their own Department of Chemical Engineering. Next year, they’ll encourage students from other departments such as mechanical engineering and electrical and computer engineering to lend their expertise.

“If you never fail it means you haven’t been pushing yourself hard enough,” Hajim School dean Wendi Heinzelman tells incoming engineering students. “What you do next – how you learn from failure and move forward so you don’t repeat mistakes – that is what really counts.”

Of the 11 members who coalesced this year, all six non-graduating students plan to continue the team next year.

And next year, they have no intentions of being stuck at the start line.